Product Model:

The slant bed two-axis CNC lathe, through its revolutionary structural design, has comprehensively surpassed the traditional flat bed lathe in terms of rigidity, precision, stability, and automation.

It is not only a mainstay of modern precision manufacturing but also the preferred equipment for enterprises to improve product quality, increase production efficiency, and achieve intelligent upgrades.

Features

This type of machine tool is the most common and mainstream mid-to-high-end CNC lathe configuration in modern manufacturing.

Its core feature is that the bed uses guide rails that form a certain angle (usually 30° or 45°) with the horizontal plane.

Compared to traditional flat-bed CNC lathes, slant-bed structures offer comprehensive performance improvements:

1. High Rigidity, High Stability, and Vibration Resistance

Triangular Mechanics Principle: The slant-bed structure is essentially a triangular support, possessing extremely high rigidity in engineering mechanics. Under the same cutting force, the deformation and vibration of the bed are far less than that of a flat-bed lathe.

Integral Casting: Typically made of high-quality cast iron in a single, integral casting, with a rational internal rib layout, further enhancing stability.

2. Smooth Chip Removal and Excellent Machining Protection

Gravity-Driven Chip Removal: Due to the inclined guideways, cutting chips and coolant naturally fall downwards under gravity, directly into the chip conveyor and being carried away.

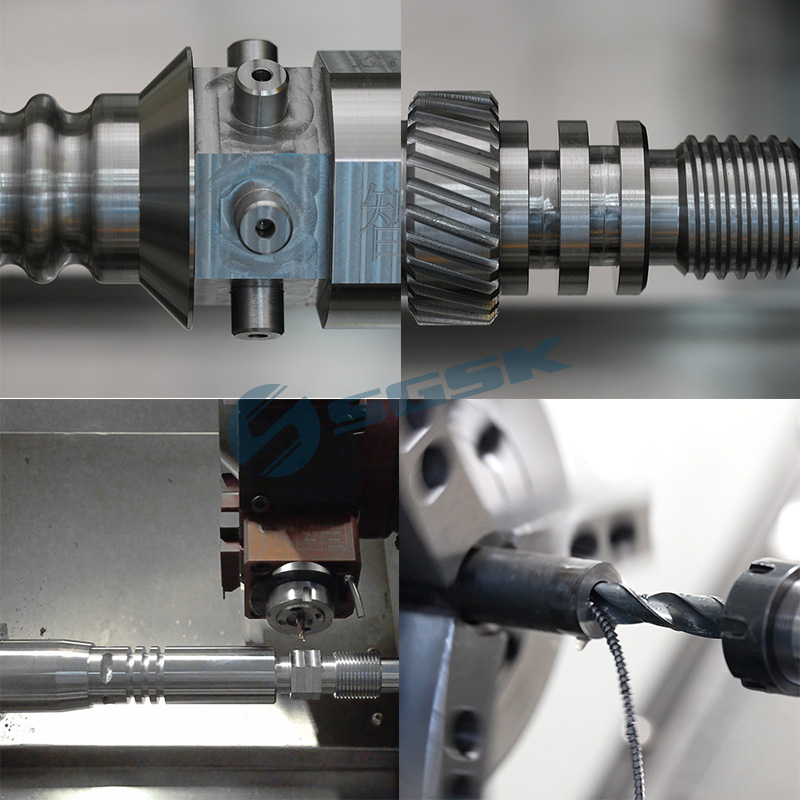

Protecting Guideways and Leadscrews: Prevents chip accumulation on the guideways and lead screws, greatly reducing wear and scratches on precision transmission components, extending machine tool life, and improving the safety of the machining environment.

3. High Precision and Precision Retention

Excellent thermal stability: Smooth chip evacuation prevents heat from chipping from affecting the machine bed and spindle. Furthermore, the spindle is typically thermally symmetrical and positioned close to the Z-axis guideway, effectively controlling thermal deformation and ensuring long-term precision stability.

High repeatability: High rigidity and an excellent drive structure (typically equipped with a pre-tensioned ball screw) ensure the toolholder maintains extremely high repeatability even during extended operation.

4. Convenient Operation and Automation Compatibility

Centralized operating area: The tool and workpiece are centrally located within the operator's field of view, making it easy to observe machining status, clamp workpieces, and tool setting.

Easy to automate: Its design easily integrates with automated equipment such as robots, articulated arms, or bar feeders, making it an ideal platform for unmanned production.

Application

Due to their superior overall performance, inclined-bed two-axis CNC lathes cover nearly all turning applications requiring precision, efficiency, and stability, making them a versatile tool for precision machinery manufacturing.

1. Precision Instruments and Medical Devices: Processing of stainless steel and titanium alloy parts requiring extremely high finish and precision, such as surgical instruments, implant joints, and endoscope components.

2. Automotive Industry: Production of engine parts (such as valves and pistons), transmission gear blanks, steering components, and brake system components.

3. Aerospace and Defense: Manufacturing of small aircraft landing gear components, engine fuel control system parts, and precision bushings for navigation systems.

4. Electronics and Communications: Processing of ceramic ferrules and connectors for optical communications equipment, as well as precision bushings and structural components within mobile phones.

5. Mold Industry: Processing of mold cores, inserts, guide pins, and bushings for precision molds.

Product Main Technical Parameters

| SPECIFICATIONS | Units | TCK36A | TCK46A | TCK50A |

| Swing over bed | mm | 360 | 460 | 500 |

| Swing over cross slide | mm | 140 | 170 | 250 |

| Max. workpiece length | mm | 300 | 350 | 350/500 |

| Spindle bore | mm | 56 | 56 | 66 |

| Bar capacity | mm | 44 | 44 | 55 |

| Spindle nose type | - | A2-5 | A2-5 | A2-6 |

| Spindle speed steps | - | Stepless | Stepless | Stepless |

| Spindle speed range | rpm | 4000 | 3500 | 3000 |

| Turret/tool post | - | Hydraulic turret 8position | ||

| Tool size | mm | 20*20 | 25*25 | 25*25 |

| X axis travel | mm | 185 | 240 | 240 |

| Z axis travel | mm | 350 | 400 | 350/500 |

| X axis rapid traverse | mm/min | 24000 | 24000 | 18000 |

| Z axis rapid traverse | mm/min | 24000 | 24000 | 18000 |

| Main motor power | kw | 5.5 | 7.5 | 11 |

| Tailstock quill diameter | mm | 65 | 70 | 70 |

| Tailstock quill taper | - | MT4 | MT5 | MT5 |

| Tailstock quill travel | mm | 60 | 80 | 80 |

| Guide rail type | - | |||

| Machine weight | kg | 2400 | 2600 | 3100/3300 |

| Overall dimension(L*W*H) | mm | 2200*1600*1850 | 2500*1950*1950 | 2600/2700*2000*2000 |

Navigation

Tel.: +86 632 5083 879

Mob.: +86 151 6326 5369

Wechat: +86 151 6326 5369

E-mail: info@gskequipment.com

WhatsApp: +86 151 6326 5369